Blog Categories

Misting Nozzles: Selecting the Right Size for Optimal Performance

Introduction

The effectiveness of a misting system is often determined by the minute yet vital component known as the misting nozzle. This guide provides an in-depth look at the various nozzle sizes, the difference between brass and stainless steel nozzles, and the specific functions of anti-drip features and nozzle filters. Furthermore, we will clarify the appropriate applications for each nozzle size.

The Spectrum of Misting Nozzle Sizes

0.006″/0.15mm Ultra-Fine Misting Nozzles

Offers a flow rate of 0.0122 GPM (0.0462 LPM) at 1000 PSI/70 bar. This nozzle is perfect for applications that demand ultra-low moisture and fine droplet size, especially effective above 500 PSI for precise humidification tasks.

0.008″/0.20mm Fine Misting Nozzles

Delivers a flow rate of 0.0208 GPM (0.0787 LPM) at 1000 PSI/70 bar. Ideal for low-flow requirements with small droplets, such as controlled humidification and cooling applications, designed for effective use above 250 PSI.

0.012″/0.30mm Versatile Misting Nozzle

Produces a flow rate of 0.029 GPM (0.1098 LPM) at 1000 PSI/70 bar. Suited for a range of applications including outdoor cooling and dust or odor management, it is compatible with pressures above 100 PSI.

0.015″/0.40mm Enhanced Flow Misting Nozzle

Provides a flow rate of 0.0398 GPM (0.1507 LPM) at 1000 PSI/70 bar. This nozzle is ideal for achieving higher flow rates with moderately sized droplets for special effects or outdoor dust control, and it can be used with any pressure setting.

0.020″/0.50mm Heavy Misting Nozzles

With the largest standard orifice, this nozzle has a flow rate of 0.0543 GPM (0.2055 LPM) at 1000 PSI/70 bar. It is primarily used in extensive applications such as outdoor demolition dust control where larger droplets are required and complete evaporation is not necessary. This nozzle is versatile across all pressure ranges.

Material Choices: Brass vs. Stainless Steel

Brass Nozzles

Brass nozzles, revered for their durability, are a great all-rounder in the nozzle market. They provide a solid balance between cost-effectiveness and performance, with good resistance to rust and wear.

Stainless Steel Nozzles

Stainless steel nozzles are the premium choice for high-pressure systems and harsh environments. Their excellent corrosion resistance ensures longevity and consistent performance, even in areas with mineral-rich water.

Enhanced Features for Misting Nozzles

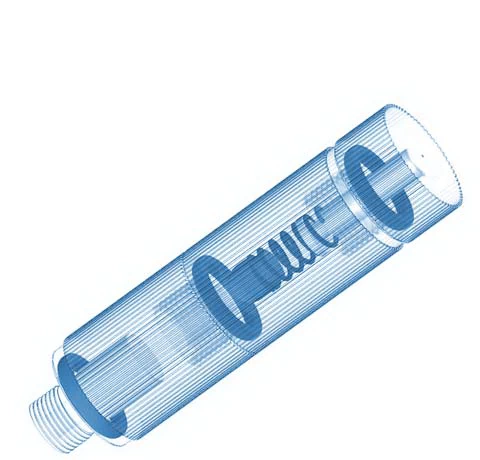

Anti-Drip Mechanisms

The misting nozzle has a simple ball and spring inside that stops water from leaking out when you turn the pump off. This way, it keeps everything dry and mess-free after you’re done using it.

Nozzle Filters

To safeguard against blockages and maintain a steady mist output, nozzle filters are indispensable, particularly in areas with hard or mineral-laden water supplies.

Conclusion

Understanding the various misting nozzle sizes and selecting the correct one is key to ensuring your misting system operates efficiently. With this guide, you’re now equipped to make an informed decision, whether you’re aiming to control humidity with precision or seeking effective cooling solutions. The appropriate nozzle can significantly enhance the efficacy of your misting system across a wide range of applications.